For product and/or process optimization and development, we use renowned cutting-edge software tools such as ANSYS-Fluent and FlareSim.

Here are some examples:

Pilot burner optimization

We continue to improve efficiency thanks to the new design of our pilot burner for flares.

This optimization process was carried out using CFD (Computational Fluid Dynamics) analysis using ANSYS-Fluent software.

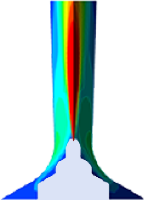

Thermal oxidizer for tail gas with high hydrogen sulfide content

In this case, the combustion of hydrogen sulfide, H2S, and its conversion to sulfur oxides is studied in a horizontal gas thermal oxidizer.

After an initial CFD simulation, the results are analyzed to improve the temperature distribution in the combustion chamber.

The geometry is then iteratively varied to optimize operation and maximize tail gas destruction efficiency.

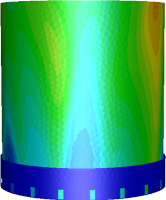

Sonic flare burner optimization

This project started with a sonic flare design and simulated it using CFD.

After analyzing the results, the gas behavior inside the burner was observed, the internals were modified to maximize the available pressure at the flare burner outlet, thus improving mixing and combustion.

The image shows the shock waves generated in the gas at supersonic speed.

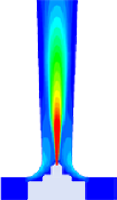

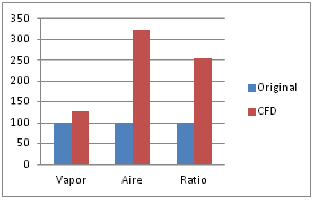

Steam and air-assisted flare burner Improvement

To improve flares combustion and reduce smoke generation, pressurized steam can be injected into the burner. Induced by the steam, air is drawn into the flare burner.

The more air injected per kilogram of steam injected, the greater the burner's efficiency and the lower the emissions.

The comparison between the old design and the one optimized using CFD shows 250% more air being injected.

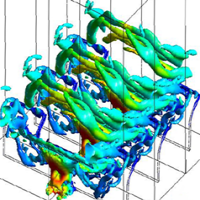

Heavy gas burner design

A new burner concept has been designed for smokeless heavy gases in ground flares.

This utilizes waste gas pressure to generate high turbulence, creating vortices that maximize gas-air mixing and combustion efficiency.

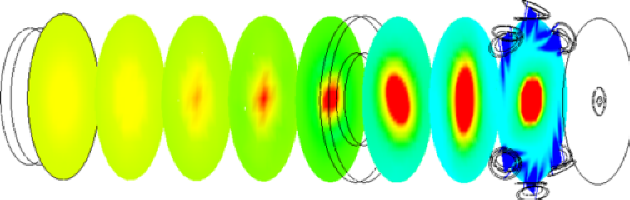

Optimization of the burners’ distribution in a ground flare

During the detailed design phase of a ground flare, the burner layout must be determined.

After an initial design, CFD simulations confirmed that the temperature limits of the refractory insulation materials were being reached, in addition to emitting gases that were not properly burned.

After a series of simulations that iterated the burner layout, the material temperature limits were not exceeded, as well as significantly improving combustion, maximizing destruction efficiency.

CFD optimization

CFD optimization